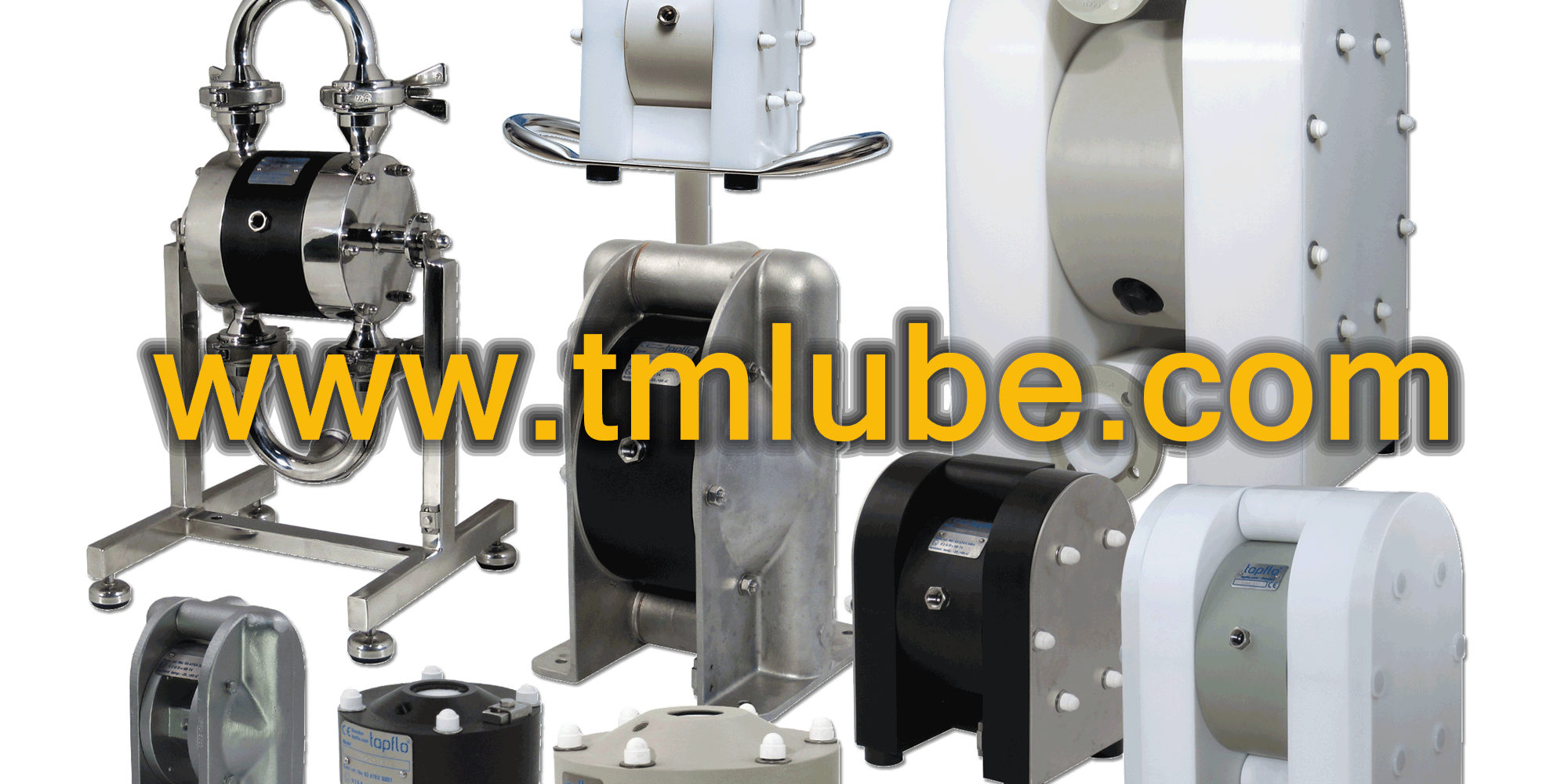

AODD pumps

Tapflo is an independent, Swedish, family owned, manufacturer and global supplier of air operated diaphragm pumps, centrifugal pumps and other industrial process equipments.

of air operated diaphragm pumps, centrifugal pumps and other industrial process equipments.

The company was founded in Kungälv, Sweden in 1980 and has since then been working with design and manufacture of thermoplastic, metal and sanitary series diaphragm pumps and also with complete range of centrifugal pumps and industrial equipment. After years of dynamic development the company evolved into Tapflo Group with worldwide operations. Tapflo Group is represented by own companies and independent distributors all over the world on 6 continents.

Pumps made from PE ( Polyethylene) plastic material can withstand 6-7 times more corrosion than PP ( Polypropylene) plastic. With the above facts, making this pump series suitable for handling abrasive sludge etc. . PE plastic is resistant to most harsh chemicals such as concentrated acids and alkalis. Maximum liquid temperature is 70°C.

PTFE (Virginpolytetrafluorethylene) is a thermoplastic polymer that is highly resistant to corrosive chemicals. Pumps made from PTFE material are used to pump extremely strong acids, for example nitric acid… Maximum fluid temperature up to 100°C.

Features and benefits:

Made from PE plastic that is 7 times better than the durability of PP plastic.

Very durable because it is molded into a solid block

The pump is made from PTFE so it can pump harsh chemicals.

A/ The PE & PTFE pump range:

TR9 - 11 l/min, 1/4”

TR20 - 24 l/min, 3/8”

T50 - 60 l/min, 1/2”

T100 - 125 l/min, 1”

T200 - 330 l/min, 1 1/2”

T400 - 570 l/min, 2”

T800 - 820 l/min, 3”

Application:

Chemistry: Acids, alkalis, alcohol, solvents, latex, emulsions

Food: CIP fluid, flavouring, pigments

Pulp & Paper: Glue, slurries, adhesives, dispersions, resins, sodium silicate, titanium oxide

Surface conditioning: Electroplating baths, various acids, solvents, anodic sludge, varnish, enamels

Water treatment: Sludge handling, filter press applications, neutralization and flocculants

Electronics: Carrier fluids, ultra pure liquids, electroplating solutions, mercury, solvents

Print & paint: Glue, additives, varnish, ink, paint, latex, acid, resins, pigments

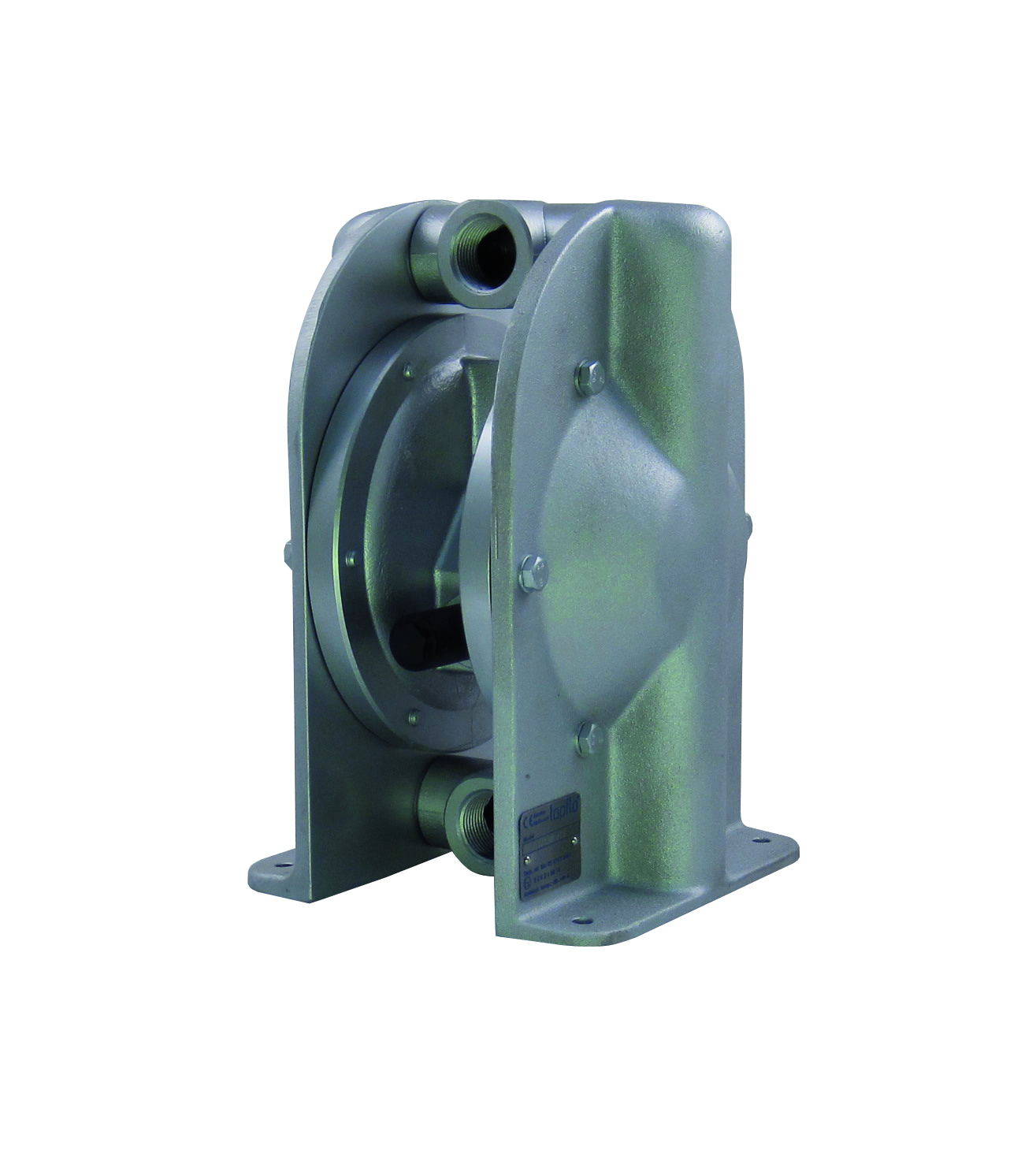

B/ The metal pump range

T25* - 26 l/min, 1/2”

T70 - 78 l/min, 3/4”

T120 - 158 l/min, 1”

T220 - 330 l/min, 1 1/2”

T420 - 570 l/min, 2”

T820 - 820 l/min, 3”

Typical applications

Workshop: Oil, fat, solvents, water, cooling fluid, lubricants

Print & paint: Glue, additives, varnish, ink, paint, latex, acid, resins, pigments

Mining & construction: Adhesives, sump, dewatering, coal sludge, pastes

Ceramic industry: Abrasives, glaze, water, enamels, clay

Chemistry: Acids, alkalis, alcohol, solvents, latex, emulsions

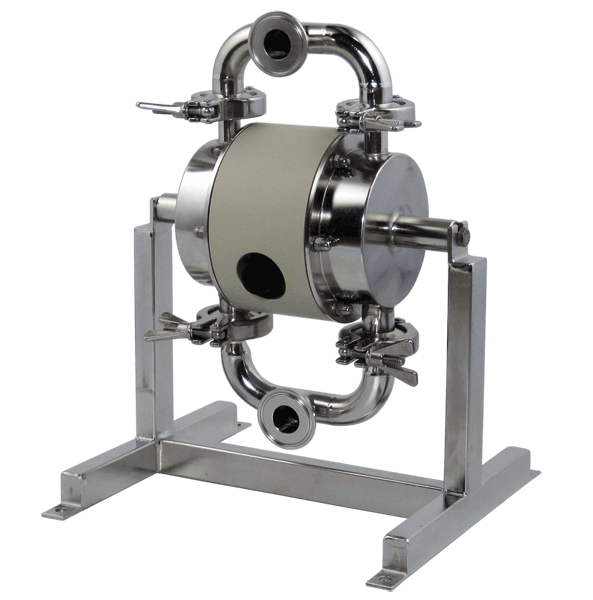

C/ The sanitary pump range

C/ The sanitary pump range

T30 - 28 l/min, 1”

T80 - 78 l/min, 1”

T125 - 155 l/min, 1 1/2”

T225 - 330 l/min, 2”

T425 - 570 l/min, 2 1/2”

T825 - 820 l/min, 3”

Typical applications

Dairy products: Milk, cream, yogurt, cream cheese, melted cheese

Grossery: Ketchup, mayonnaise, tomato products, mustard

Beverages: Flavours, colouring, fruit juice

Bakery: Dough, ingredients

Brewery:Beer, flavours, colouring, wort

Hygiene; Soap, toothpaste, shampoo

Cosmetics: Cream, alcohol, perfume

More information please visit at website: www.tapflo.com